Emergency power systems aren’t called upon in ideal situations. And your emergency power supply system (EPSS) needs to be designed to kick on in flood, earthquake, fire and storm conditions (A.5.1.1).

National Fire Protection Agency standard 110 —the standard for emergency and standby power systems— outlines ways to prevent the disruption of life safety critical loads in case of emergency. It also lists the tests required to prove compliance with the authorities having jurisdiction (AHJ), the agencies responsible for code enforcement in your area.

Your EPSS will ultimately be installed, tested and maintained by your gen set manufacturer and approved by the authorities having jurisdiction (AHJ). Because your particular AHJ will vary depending on your location, there’s no cut-and-paste way to achieve compliance. You’ll need to carefully read NFPA 110 and talk with your AHJ to make your EPSS installation compliant with all applicable standards and codes.

Your generator manufacturer —if familiar with NFPA 110— is another excellent resource to lean on throughout your journey to compliance. At CK Power, our system engineers are well-versed in NFPA 110, and other applicable standards, and can assist you in achieving compliance for your emergency power system.

Through every stage of the EPSS approval process —design, installation, maintenance and testing— our engineers will be on your side, offering cost-effective, compliant solutions tailored to your particular application. They’ll also consider applicable codes, standards and requirements beyond NFPA 110 in the development of your maintenance and testing plan.

From design to ongoing maintenance, there’s a lot to think about when seeking to comply with NFPA 110. We’re going to take you through highlights of each step of the process, so you can know the right questions to ask and things to consider when developing a compliant EPSS with your generator manufacturer. For a complete guide to compliance, download our straightforward guide to NFPA 110.

NFPA 110 Chapter 7: Installation acceptance testing

Chapter 7 of NFPA 110 —entitled “Installation and Environmental Considerations”— provides minimum installation requirements designed to prevent the disruption of life safety critical loads in case of emergency. It also outlines the tests required to prove compliance with your AHJ.

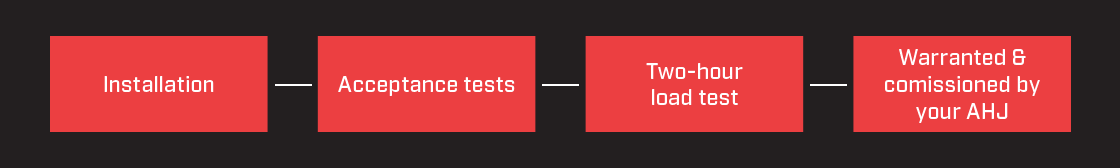

Your EPSS is not considered compliant upon installation — you must prove its function and ability to carry all emergency loads (7.13.1) through a series of on-site installation acceptance tests and a two-hour load test (7.13.4.3) with the AHJ present (7.13.3).

Along with assistance from your generator manufacturer, you’ll test your EPSS installation and ensure it both follows NFPA guidelines and is acceptable to your AHJ. After passing the tests, your equipment will be warranted and commissioned by your AHJ for use as an emergency power system.

The NFPA doesn’t certify any equipment or installations — your AHJ does. If you want to achieve compliance for your EPSS installation, you’ll need to reference your manufacturer’s recommendations and work closely with the AHJ in addition to following NFPA 110 (7.1.3). Ultimately, though, the AHJ has final say in whether or not your EPSS installation is compliant.

NFPA 110 Chapter 8: Ongoing maintenance and testing requirements

Your EPSS must provide reliable power at a moment’s notice. And since you can’t predict when you’ll need to call upon your emergency power system, routine maintenance and testing is the only way to make sure the system is functioning and ready to kick on at all times.

NFPA 110 Chapter 8 outlines the minimum requirements for maintaining and testing your system. Notably, this is the only section of the standard that applies to both new and existing emergency power systems (1.3). Whether your system was installed yesterday or five years ago, the provisions in Chapter 8 apply to you and your EPSS.

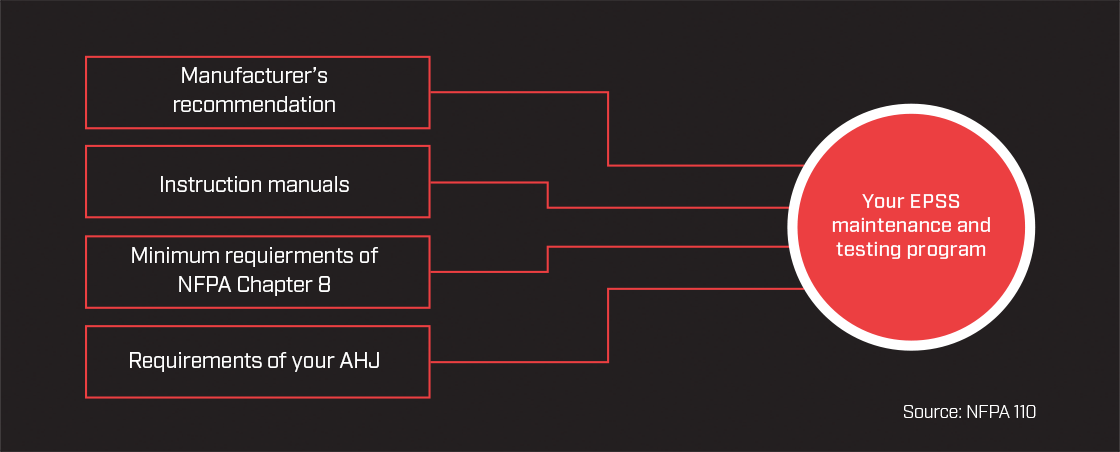

Since every system is different, the NFPA recommends you base your particular maintenance program on your AHJ’s standards, your equipment instruction manuals and your generator manufacturer’s recommendations (8.1.1).

And while NFPA 110 serves as a good reference for recommended practices and standards, the NFPA doesn’t certify any maintenance programs or enforce any of their recommendations. A maintenance program is “approved” when it is deemed acceptable to the AHJ — the agency or agencies responsible for enforcing code compliance in your area.

To assist in the development and execution of a compliant maintenance and testing program, the NFPA suggests you seek professional advice and work closely with the AHJ throughout the process. To this end, your generator manufacturer’s compliance specialist is a good resource, especially during installation design and maintenance plan development.

Minimum maintenance requirements in NFPA 110 Chapter 8

NFPA 110 Chapter 8 suggests you follow your manufacturer’s maintenance recommendations, but outlines an alternate maintenance program if no manufacturer-given guidelines are available (A.8.3.1). This sample EPSS maintenance plan is provided in Figures A.8.3.1(a) and A.8.3.1(b).

Their alternative recommendations are helpful in visualizing the weekly, quarterly, monthly and annual inspection / maintenance items you’ll have to perform. However, it isn’t necessarily an exact replica of what your plan will look like. And following it won’t guarantee compliance — the NFPA only provides the sample plan for informational purposes.

Your particular system’s maintenance program will depend largely on your manufacturer’s recommendations and your AHJ’s requirements.

Maintenance is a big part of what we do at CK Power. We’ll help design a maintenance program to overcome your facility’s particular challenges, such as storing / maintaining your fuel supply and ensuring the continued integrity of your system’s transfer equipment.

Generator testing: Ongoing requirements according to NFPA 110 Chapter 8

In addition to routine maintenance, you’ll also need to conduct ongoing operational tests of your EPSS. The purpose of these tests are to periodically verify the function of the system against the standard.

It’s worth noting that your specific testing requirements might vary based on your manufacturer’s recommendations and the requirements of your AHJ. You’ll need to work closely with your generator manufacturer to develop a compliant EPSS operational testing schedule.

Generally speaking, you’ll need to perform a weekly inspection and a monthly load test on your EPSS (8.4.1). And every 36 months, you’ll need to run Level 1 EPSS systems for the amount of time specified in your application’s Class up to four hours of runtime (8.4.9.1-2).

You’ll also need to create and store up-to-date records of all maintenance and testing you perform. These reports should include the date, personnel, notes of any problems, and documentation of the process you took to rectify any problems (8.5). The AHJ should have requirements about how long you should keep reports available for inspection.

If you’re trying to achieve compliance for your facility’s emergency power system, closely reading NFPA 110 is a good place to start. From there, you’ll need to work with the governmental agencies responsible for code enforcement in your area. And along the way, your generator manufacturer should be able to answer any questions you might have about the installation, maintenance, operation and testing of a compliant NFPA EPSS.

For more information about the standard, read our no-nonsense guide to NFPA 110 compliance for emergency power systems. You’ll get a straightforward explanation of what NFPA 110 is, what it means for your facility and guidance on how to work with the NFPA, enforcement agencies and your generator manufacturer to achieve compliance. Download the guide now.