Final Tier 4 regulations from the Environmental Protection Agency (EPA) went into effect at the end of the 2015 calendar year. These regulations on diesel engines target specific emission byproducts that cause harm to the environment and to the humans who inhale them.

While these regulations have been in place for a few years, we often get questions about Tier 4 diesel engine problems. Here are some common ones. If you don’t find the solution you’re looking for, get in touch with our team.

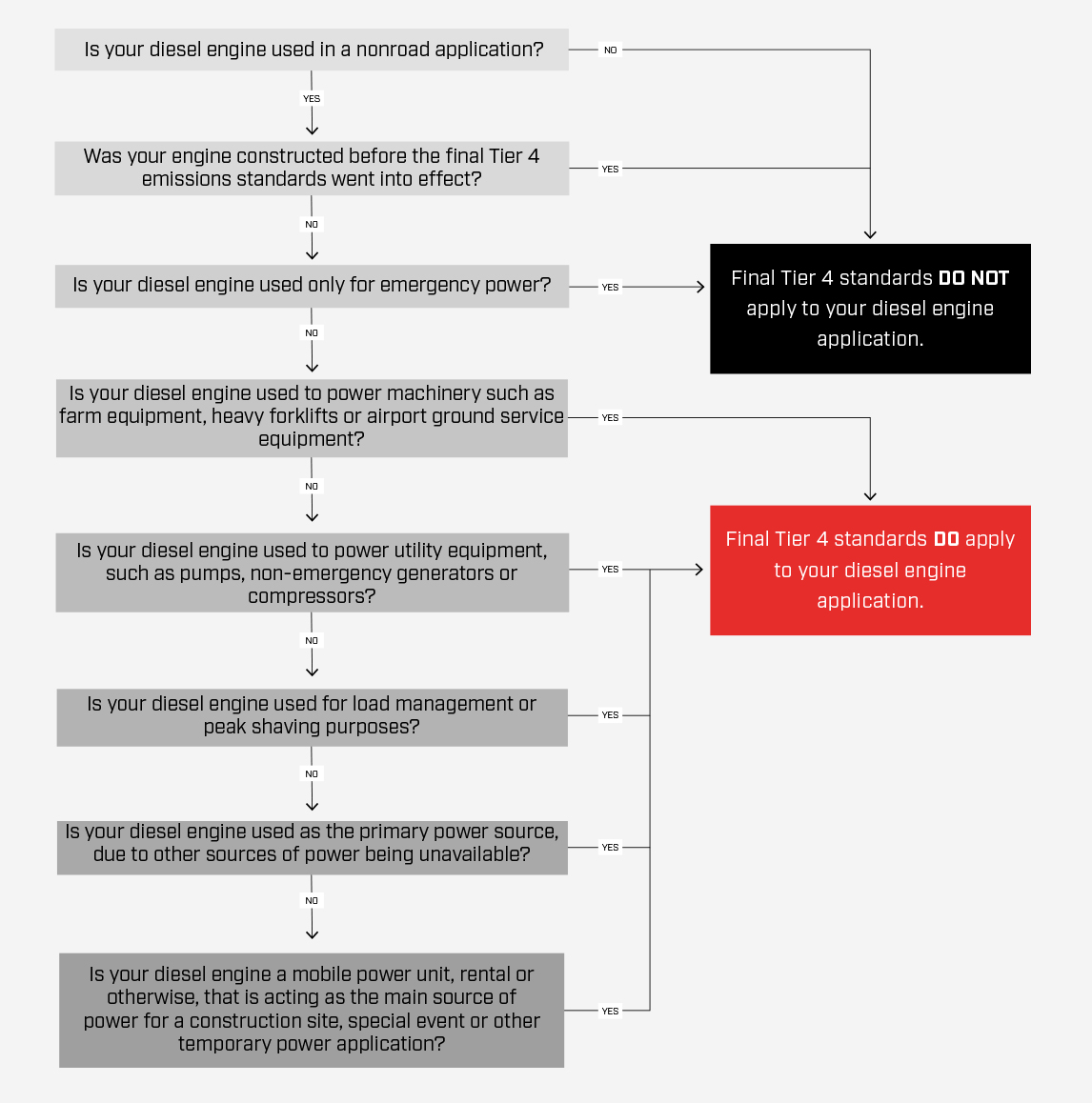

Do final Tier 4 standards apply to my diesel engine?

Depending on your application and the age of your engine, final Tier 4 standards might not apply to you. If you’re unsure whether the regulations impact your particular application, the flowchart below can help. Start at the top and work your way down.

Still unsure if the regulations apply to you? We offer Tier 4 consultations to help answer your questions and find solutions.

Common Tier 4 engine problems

How do I order final Tier 4 engine equipment?

Many customers have been ordering engine equipment from us for years. And it was easy. The manufacturer would send us horsepower requirements, and we’d provide a menu of options. The customer would choose and that was that.

But now the buying process has changed. Not only has the menu of options changed, but some dealers are also sending complicated estimates to manufacturers and some quotes don’t include the crucial components needed to meet Tier 4 standards.

When you work with CK Power, ordering final Tier 4 equipment is simple. Our sales and engineering teams listen to your challenges, questions and needs, then recommend the product best suited for you. From there we refine the specs and customize your engine as needed, all while remaining at or under your budget.

The service doesn’t stop once we deliver your engine. Our cradle-to-grave support will keep your equipment running like new for years to come.

Tier 4 says I need more space to mount my engine. What do I do now?

If these base constraints sound familiar, you’re not alone. We’ve been hearing them more and more, often from manufacturers who buy directly from an engine manufacturer. For many of those companies, the relationship might end with the sale. But in situations like these, expert service is paramount.

Depending on the modifications you need to make, like a complete redesign or a standard “drop in” power unit, we can help you reorient your engine’s parts to minimize impact and cost while avoiding a full overhaul.

Which Tier 4 diesel engines require regeneration time?

To burn off excess particulate matter to meet Tier 4 emissions standards, the diesel particulate filters on some final Tier 4 engines will periodically need to function above normal operating temperatures for a time. Since they cannot be used while performing this function, this creates downtime.

To learn more about CK Power’s engine offerings, check out our John Deere and Kubota product pages.

How can I prevent wet stacking?

Wet stacking refers to the buildup of unburned fuel on the cylinder walls, and throughout the exhaust system. You can visually detect it by looking for thick, black liquid in the exhaust pipe. This liquid is the combination of unburned fuel (soot) and exhaust.

It’s caused by underloading your generators, and Tier 4 engines are especially susceptible to this. To prevents this, you must size your generator appropriately for the load it will carry. Learn more here.

Are there Tier 4 solutions for high kW generators?

Yes, there are. We invested in the engineering early on and made some of the first high-power Tier 4 solutions in the country. With a range of 500 kW to 1,250 kW, customers across applications have been using our high-power generators for years.

Learn more about our line of higher kW generators here.

I have in-service equipment powered by a lower tiered engine that I need to replace. Can I switch in a Tier 4 diesel engine?

Because of their size and performance characteristics, doing a like-for-like replacement of a lower tiered engine with a Tier 4 diesel engine isn’t always possible. However, Tier 4 regulations have a few exceptions in place that allow you to use engines from Tiers 1, 2, 3 and 4-interim (4i) to repower legacy equipment.

CK Power has two EPA-compliant programs to help you do this: an engine replacement/swap program, and an equipment refurb/replace program.

To learn more about repowering off-highway diesel equipment, read this article.

How have individual engine manufacturers adapted to Tier 4 regulations?

John Deere, Volvo Penta and Kubota have all come up with innovative new technologies for their various diesel engines. To learn more about how each manufacturer cut emissions to meet standards, check out this article about clean diesel technology, or keep reading below.

John Deere Tier 4 engine solutions

To address Tier 4 engine problems introduced by the new standards, the John Deere Integrated Emissions Control (IEC) system uses two strategies: selective catalytic reduction and cooled exhaust gas recirculation.

What is selective catalytic reduction?

Selective catalytic reduction (SCR) and diesel oxidation catalyst (DOC) is the first of the strategies John Deere uses to reduce emissions. It works by raising the combustion temperatures the engine operates at, which leads to a more thorough burn off of particulate matter. As a result of the oxidation that takes place in the DOC, the remaining particulate matter turns into less harmful byproducts.

This accomplishes half of the standards’ target, but the higher operating temperatures have the unfortunate effect of creating more NOx. To lower the NOx emissions, a diesel exhaust fluid (DEF) is introduced into the exhaust stream. When the exhaust combines with the exhaust fluid, the NOx breaks down into nitrogen gas and water vapor.

What is cooled exhaust gas recirculation?

Cooled exhaust gas recirculation is the second strategy John Deere engines use. It works by mixing measured amounts of outside air to reduce the amount of particulate matter in the system. The remaining particulate matter then passes through a diesel particulate filter, which traps the remaining particulates. Next, using heat from the engine itself, the particulate matter oxidized to create nitrogen gas and carbon dioxide. These byproducts are released as exhaust.

Volvo Penta Tier 4 engine solutions

Volvo Penta engines also make use of selective catalytic reduction (see John Deere section above) to meet emissions standards. In addition, these engines also use an exhaust gas recirculation (EGR) air throttle system.

What is exhaust gas recirculation?

An exhaust gas recirculation air throttle systems helps reduce the amount of NOx emitted by the engine as a result of selective catalytic reduction (SCR). The air throttle controls the amount of air entering the engine, which in turn affects the exhaust temperature that determines how much particulate matter burns off during SCR. The throttle closes partially during light loading to maintain the necessary engine temperature for meeting those requirements.

These combined strategies help to both reduce wear in the engine over time and prevent the need for downtime caused by regeneration.

Kubota Tier 4 engine solutions

Kubota also uses cooled exhaust gas recirculation (EGR) air management technology to reduce NOx emissions at a lower combustion temperature (see Volvo Penta section above). This leads to more efficient combustion and better performance. The engines also utilize a wall flow filtration system to trap excess particulate matter plus a diesel particulate filter after-filtration for cleaner exhaust.

Check out the video below for an animated representation of these technologies.

Solving your Tier 4 engine problems

Hopefully we’ve addressed the issues you’ve encountered while satisfying the EPA’s final Tier 4 engine regulations. But if we haven’t, let’s talk. Schedule a Tier 4 consultation today and we’ll help you find a solution.